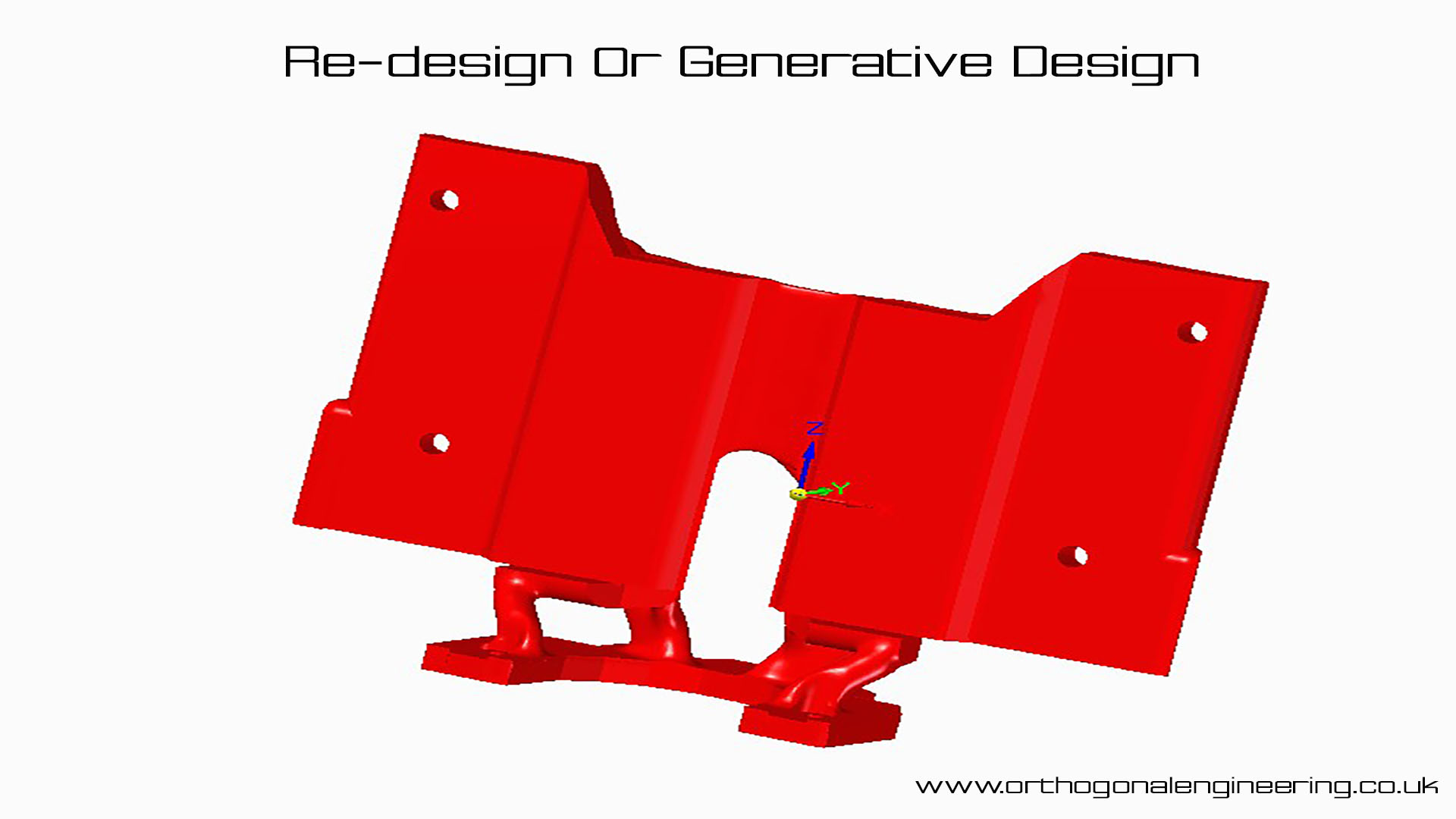

3D Design, Engineering & Reverse Engineering

About Additive Manufacturing / 3D Printing

Collaborative design.

Orthogonal always utilises a fully collaborative design and and manufacturing process - keeping you in control.

Design for additive Manufacturing

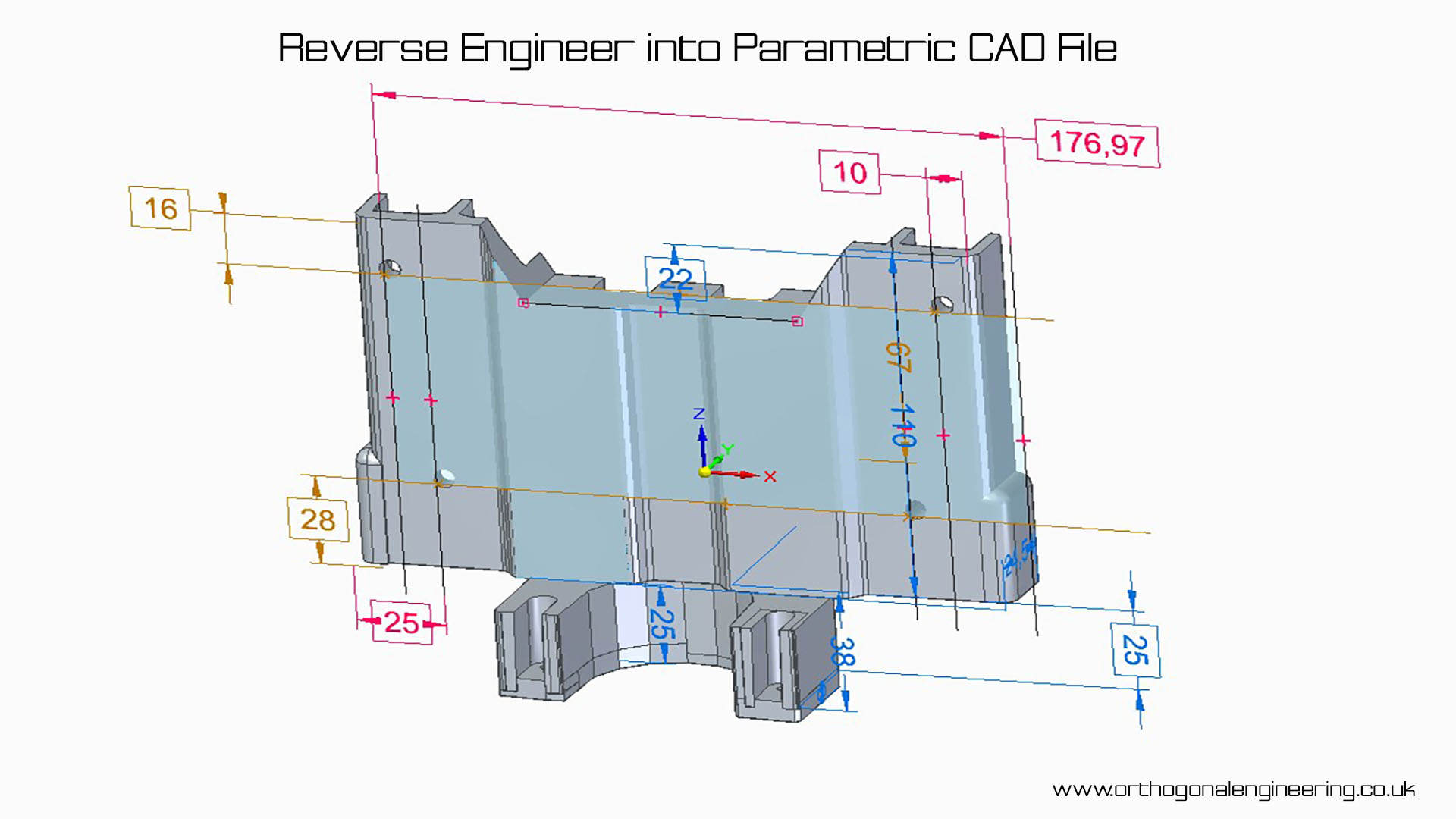

Our know-how and experience with High Temperature Polymers and expertise in DfAM - Design for Additive Manufacturing - provides you with full engineering support, ensuring that manufactured parts meet the required operating standards and tolerances (ISO2768 Medium) to ensure that your parts assemble as expected. Full process control and traceability provide you with confidence on part accuracy, repeatability and conformance.

Architectural Models

As well as engineering grade prototype and end use parts, we also produce highly detailed scaled equipment demonstration models and Architectural models - Get in touch for more details.

Don’t accept your current supply chain manufacturing constraints, talk to Orthogonal Engineering today – there’s always a better way!

Before

After

Combined

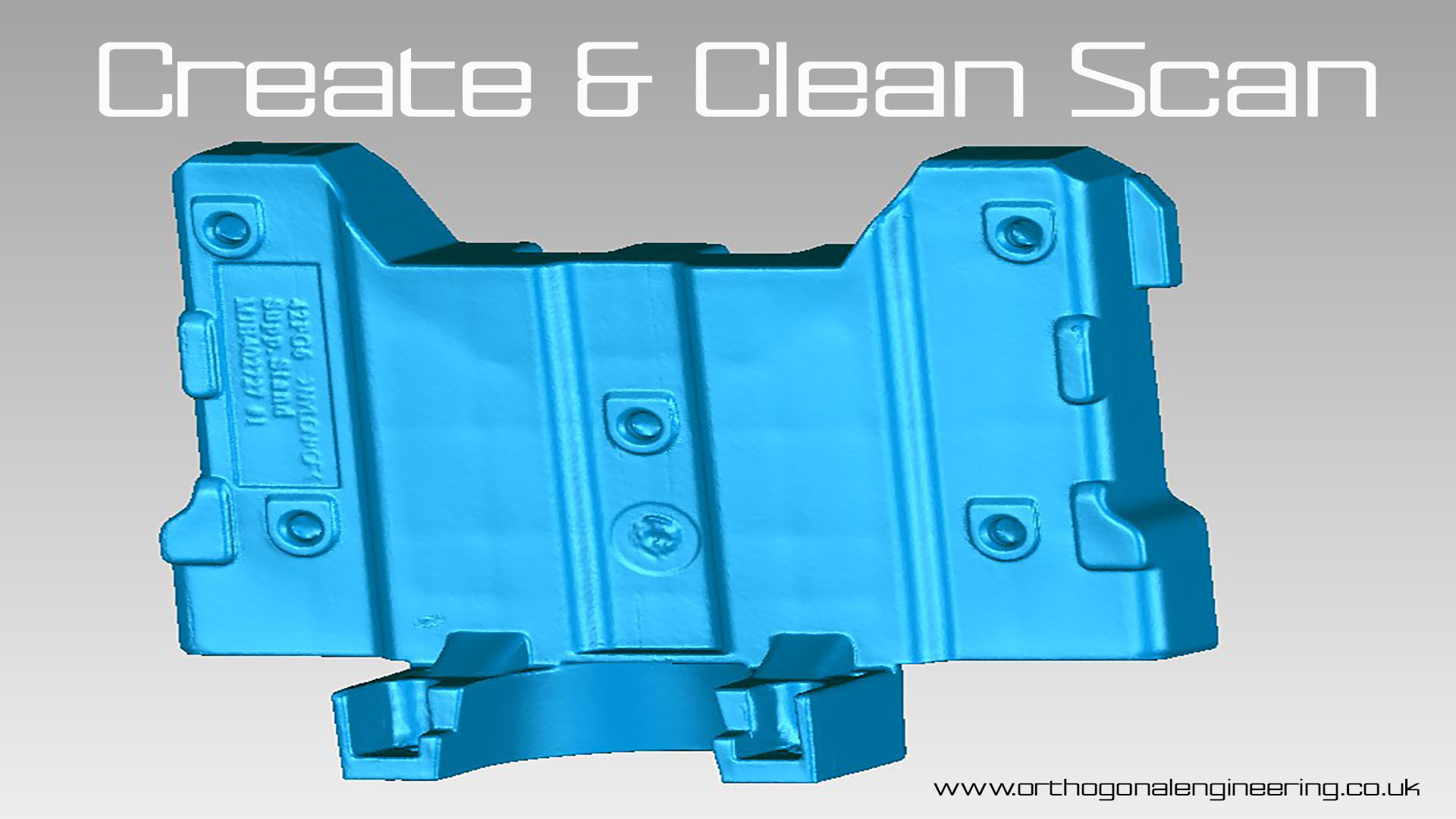

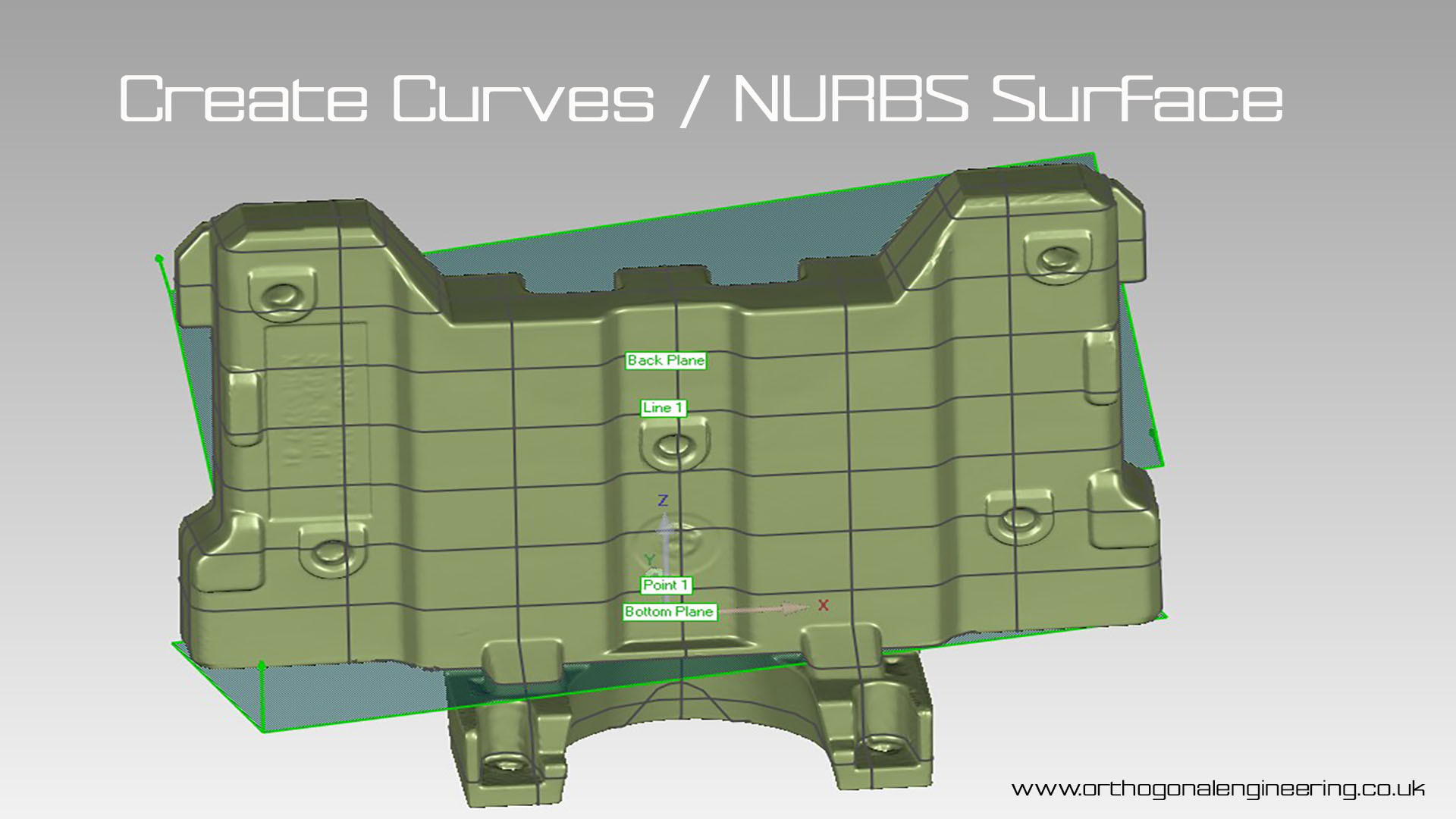

3D Scanning / Reverse Engineering

3D Printing

3D printing in Metal, PEEK, ULTEM, Carbon Fibre Composites or Engineering Thermoplastics and Resins.

We can use either Fused Filament Fabrication or Low Force Stereolithography 3D printers.

High Temperature FDM Printer

SLA & Standard FDM Printers

Call

© Orthogonal Engineering Ltd